Top 5 Must-Have Field Service Management Software Features

Field service management (FSM) software has become an essential tool for businesses that provide on-site services. It helps streamline operations,...

3 min read

Kaitlin Nelson

:

Dec 14, 2023 10:25:06 AM

Kaitlin Nelson

:

Dec 14, 2023 10:25:06 AM

Manufacturing without MRP is like trying to drive through rain without wipers. You can do it, but not as well as if you had a clear windshield. To reach your full potential you need Acumatica MRP.

MRP within a Manufacturing ERP System helps you:

MRP (Material Requirements Planning) is a system that helps manufacturers plan out what materials they need and when they need it. MRP essentially helps manufacturers produce the right amount of inventory at the right time so that you don’t overstock or understock inventory.

Overstocking your inventory ties up your cashflow, making your operation less efficient and less profitable. On the other hand, understocking your inventory leads to delays in your product, significantly reducing satisfaction among your customers. It’s a balancing act and with MRP at the forefront of your operation you can much more accurately predict how much inventory you need to make in a given time.

In fact, in certain MRP systems, you can receive alerts as to when you need to order more parts and the system tells you if there is a delay in your supply chain ahead of time so you can react accordingly. MRP is the gift giver of time; time to react to changes in the marketplace and time to invest your energy where it’s needed most: behind strategy, not tactics.

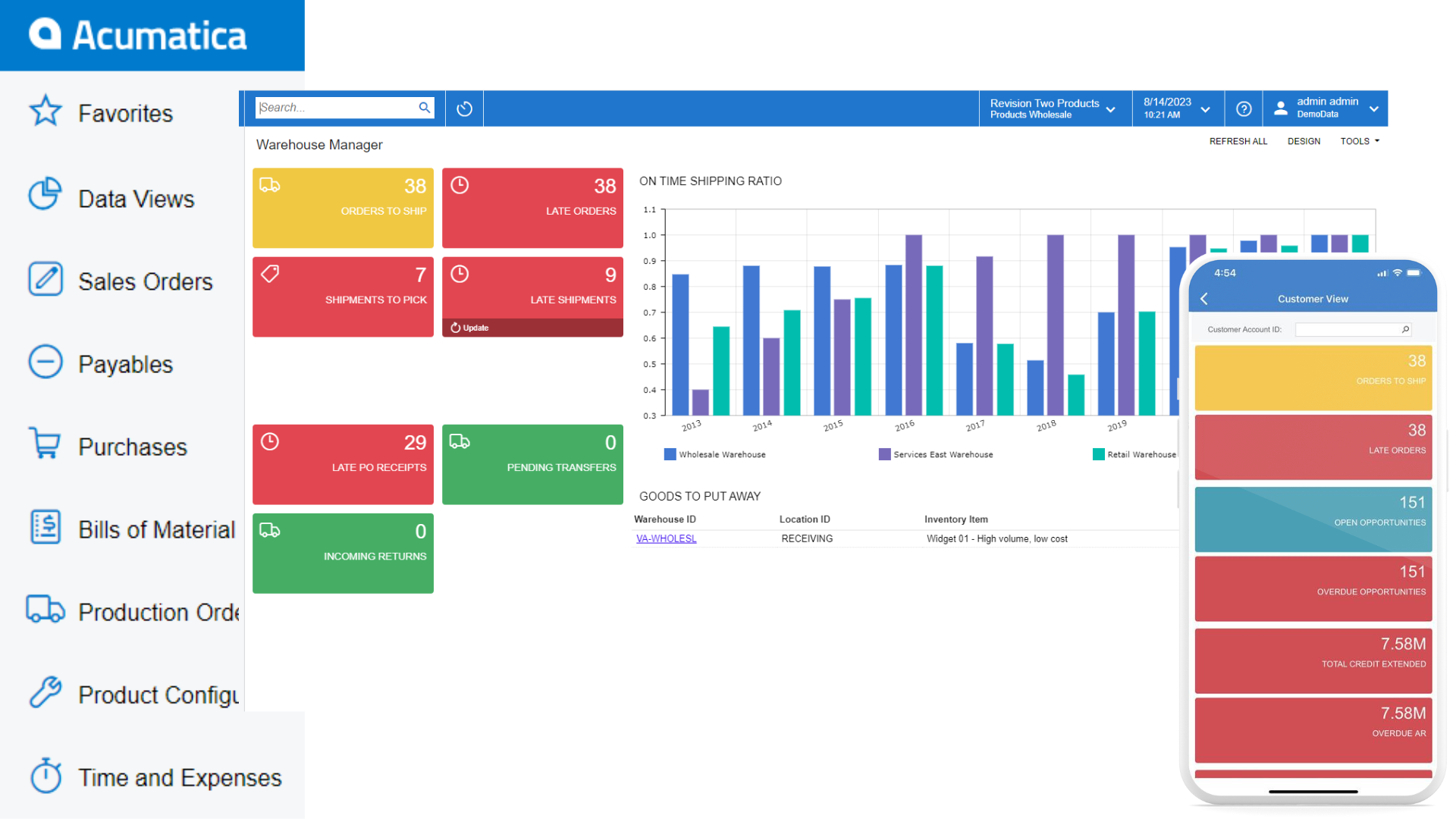

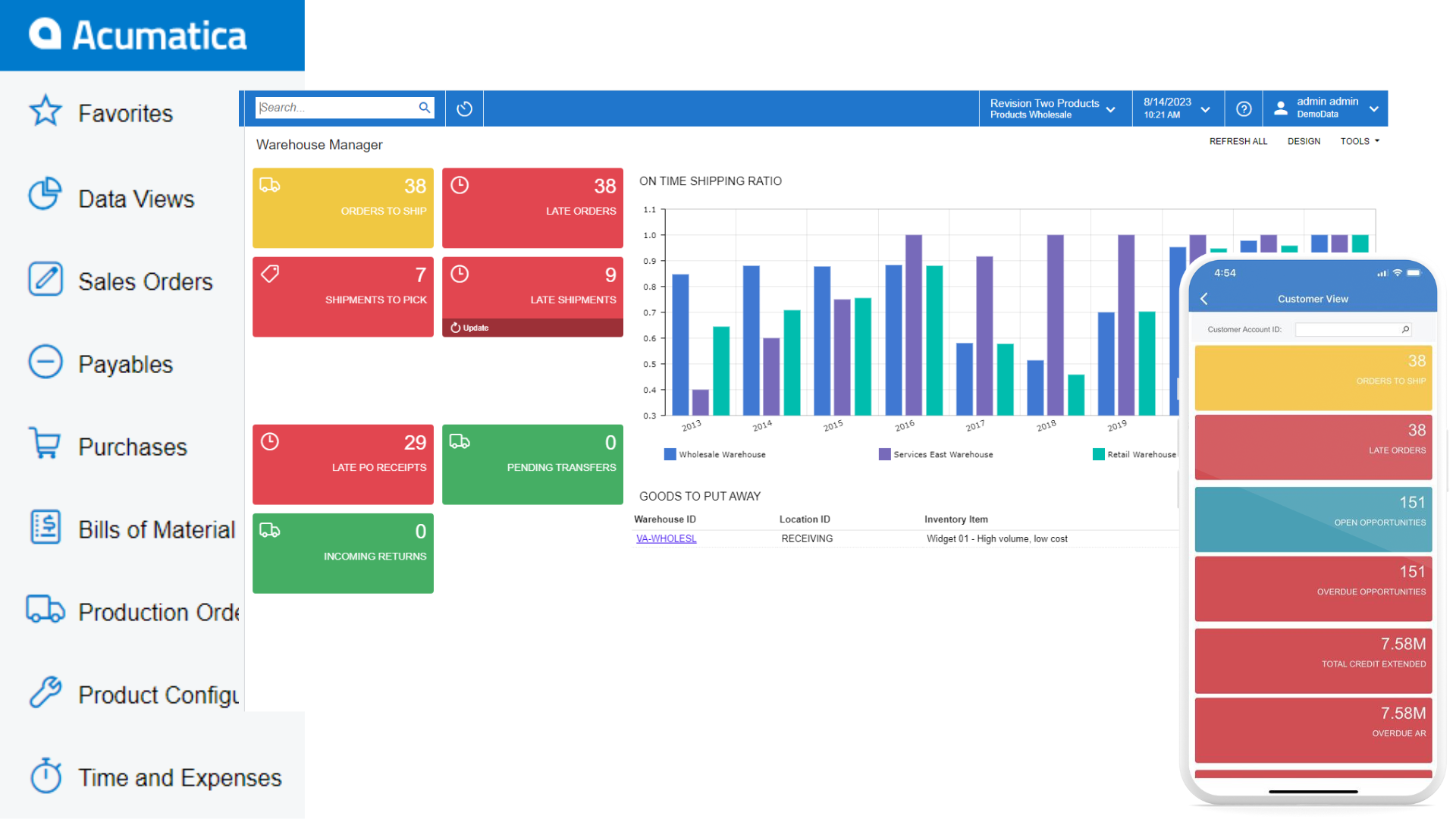

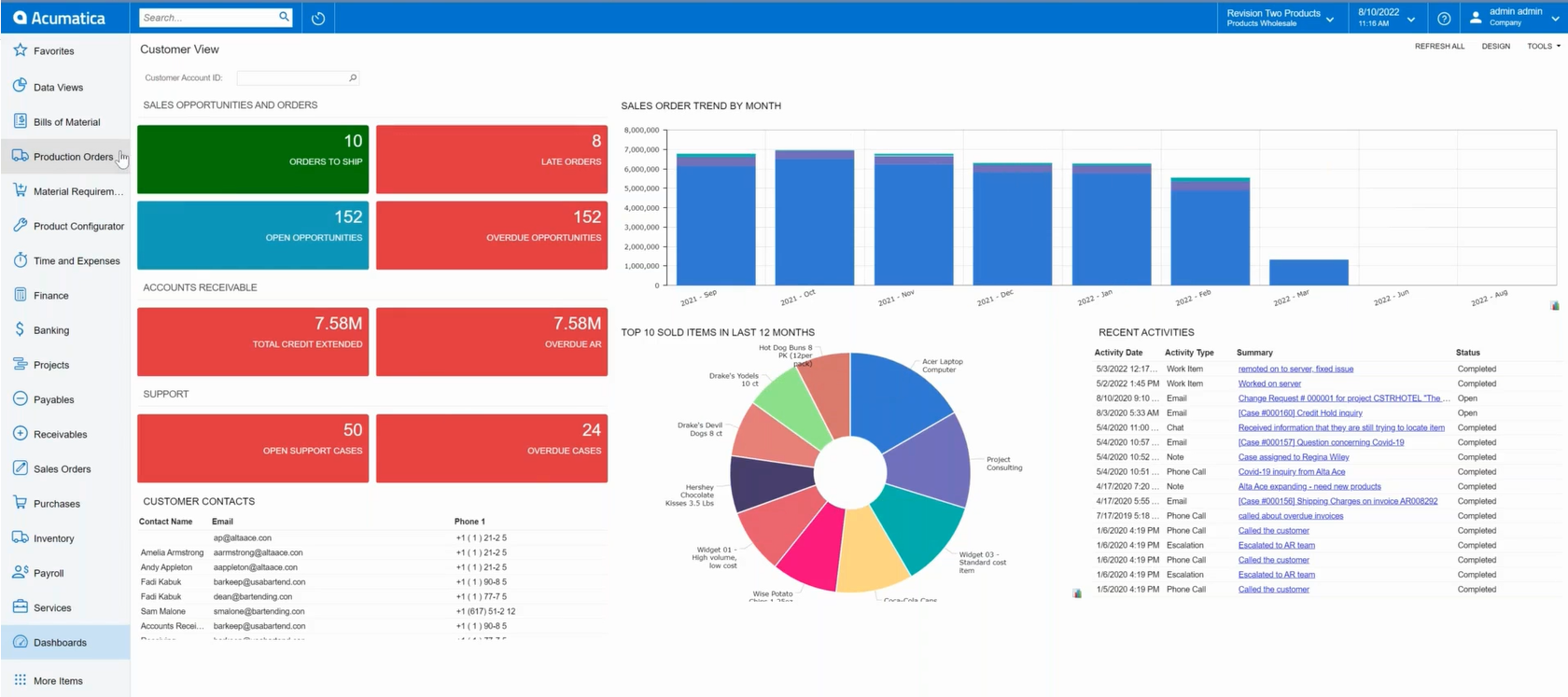

When you don’t have MRP, you become more reactive and less proactive. This is a direct result of not being able to see what’s happening. What does your inventory process look like? How do you know when you have to manufacture more products or order more parts? You may have to walk out to the shop floor to manually count how many materials or parts you have left and then determine which ones are already allocated to other demands. Do you find yourself calling various coworkers looking for answers? All these actions WASTE time! With MRP in place, you eliminate going out to the floor altogether. In an MRP system, you have access to see what materials you have on hand from anywhere.

In a solution like Acumatica, you can even set up notifications for reminders or alerts when inventory gets too low and have the system reorder parts automatically. Say goodbye to manual processes and hello to your new time saving machine.

None of us are strangers to supply chain disruptions, whether they’re from global outbreaks or economic volatility. Take a moment to think back to what happened just over the past two years. People scrambling, working overtime to source the products that became scarce. Frustrated customers wondering why their order was delayed…or worse unavailable to even purchase. To say it was chaos would be an understatement. Now imagine if you could have been better prepared to respond to these disruptions. Imagine an alert notifying you of a potential shortage. As people, we’re good at pattern recognition, but machines? They can crunch the numbers quickly across multiple data inputs to provide tailored guidance on what is needed and when. MRP lets you know ahead of time that there could be potential delays in materials arriving. MRP gives you the tactical data you need to make an informed decision in order to respond effectively. Let’s say MRP spots a delay in shipments over the next month. MRP can help notify you based off a shortage or based upon a recent increase in demand. You can turn around with that information and diversify your risk by calling up an additional supplier for more inventory before the problem occurs. This lets you address issues before they become problems, solidify your advantage over your competitors while responding effectively to these challenges.

Without MRP, it can be a struggle to meet the demand of your clients. Without visibility into your system, your manufacturing processes are clunky and slower to respond. MRP smooths the process of planning and scheduling production to make sure parts and materials get to where they need to be in the most efficient way to fulfill customer orders on time. With MRP in your operation, you’ll be filling current customer orders and freeing up capacity to take on new customers.

Without MRP, it can be a struggle to meet the demand of your clients. Without visibility into your system, your manufacturing processes are clunky and slower to respond. MRP smooths the process of planning and scheduling production to make sure parts and materials get to where they need to be in the most efficient way to fulfill customer orders on time. With MRP in your operation, you’ll be filling current customer orders and freeing up capacity to take on new customers.

MRP can help you grow to reach your full potential, but how exactly do you reap the benefits above? First you need to assess which system will best meet your needs. One of the best ways to do this is to hire an ERP consulting team to help you evaluate which system can fit your needs the best. At Lucid Consulting, we are committed to making sure the system you choose satisfies your unique needs so you can grow to your full potential. Choose your team and system correctly and you’ll be driving your business forward with clear visibility.

To learn more about how MRP can make you the best manufacturer you can be, watch our on demand webinar.

Contact us today to see if Acumatica is the right fit for your manufacturing business.

Field service management (FSM) software has become an essential tool for businesses that provide on-site services. It helps streamline operations,...

Do you want your business to thrive or just...survive? To thrive in today's environment you primarily need two things to thrive: the right people and...